Ten Radio Control Mistakes to Avoid

Our goal at Crashtesthobby.com is to help you have fun flying radio control planes. We believe in planes that fly well that will last and can survive the crashes and abuse that come from flying. The difference between success and failure is usually your attention to detail in your building, set up and your pre-flight preparation. This article will address the most common problems we see and the most frequently asked questions we get from flyers.

I would have saved hundreds of dollars if I had received better advice when I started flying radio control. In these articles we are going to tell you how to build high quality, high performance planes that don't break and still fly on a budget. We try to keep things inexpensive and simple. Watch our videos. Read the articles on our web site. We love to fly and think that you will too if you get durable products and good information.

Full sized aircraft are required to have a pre-flight checklist. Surgeons in the hospital do a pre-op checklist. In RC we should follow their example and go through an equipment and safety checklist to make sure we are ready to fly. If you have flown and the plane is not flying right it is a good idea to review the checklist below to help you figure out what may be going on before you fly again. Once your plane is in the air you are committed to a landing.

The number one easily preventable problem we see is planes that are tail heavy. You need to know where the center of gravity location on your specific plane is supposed to be. You have to get the CG correct even if you have to add lead to the nose of the plane. No exceptions!!! Even a little bit tail heavy will make a big difference. Your plane won't fly well if it isn't balanced correctly. The center of gravity is balanced on the wing, not on the fuselage. Even if you move the wing on the fuselage you will still measure the CG distance back on the wing to balance your plane.

The CG is a point at which the plane needs to balance if it is going to fly well. On a flying wing The CG is back about 23% of the total wing area including elevons. This means that 77% of your plane and the motor are behind the center of gravity. On a conventional plane with a tail the CG can be back as far as 32% with 68% of the length of the plane behind the CG. With most of the plane behind the CG you still have to make it balance. Placement of the battery and radio help to move the CG forward but it is also just as important to keep the back or tail of the plane light. It takes 2-3 ounces of lead in the nose to balance one oz of added weight in the tail.

Tail heavy planes often are diagnosed with other problems because they fly erratically. Many people think that their radio is broken or the plane is not designed well when it is just a center of gravity problem. If your plane rolls over when you try to loop it may be tail heavy. If you are having trouble controlling your plane when you launch it may be tail heavy.

If your plane is nose heavy it won't pull up in a glide and the plane will feel under powered especially at lower speeds.

Put some thumb tacks in the bottom of your plane on the right and left wing back at the suggested center of gravity for your specific plane. Balance your plane on your fingers with your fingers on the thumb tacks. The plane should be neutral and not fall forward or back. Add weight or move your battery to get the plane to balance.

Make sure you get the right plane for your skill level. About half of the people who contact us about getting started in FPV don't know how to fly. Other new flyers tell us that they want to build a ballistic Scythe that will fly 100+ mph and they haven't ever flown a Albatross that can fly 10-30 mph. Many people find us looking for EPP foam planes that last because they have had a frustrating experience with their fragile plane, heli or quad. Enjoy the learning process. We have planes for all skill levels and you will have more fun if you get an easy flyer like the Albatross to start with especially if you don't have someone helping you. Flying wings are durable but they do fly faster. Start simple and work your way to the more complex and aerobatic planes.

Lighter flies better ... a lot better!!! It is logical if you think about it. If your plane is as heavy as a brick it will fly like a brick. If it is as light as a feather it floats like a feather. Heavy planes take more speed to fly and are quicker to stall or snap roll and not respond well radio commands. Planes with big motors, heavy batteries, FPV gear and cameras end up weighing more so they are harder to launch, harder to fly, more likely to roll over during launch and will want to land faster. Some of the best flying planes I have owned are planes I built light.

Plane weight is not calculated just by weight but by wing loading. Wing loading which is calculated in the USA by the weight in ounces divided by the area of the wing in square feet. Gliders and indoor planes can be under 4 oz/ft2 wing loading. Flying wings are about 10 oz/ft2. I have seen FPV planes loaded with batteries close to 20 oz/ft2. You can get the feel of how your plane is going to fly just by feeling the weight.

Use the right prop and get it on frontwards. The thickest part of the prop should be facing forward whether the prop is in the front or the back of the plane. The front of the prop usually has lettering on it. It is easy to get confused and put the prop on backwards if you have both nose mount and pusher planes. The prop will still push air the right direction if it is on backwards but it will only have about 1/3 the power and it will make a buzzing sound that isn't heard if it is on correctly.

We often see flyers trying to use a slow fly prop on a high power motor. These props are too soft and flatten out and don't give much power at higher RPM. Use the APC style props for the best power on the higher power motors. We sell prop adapters on our web site that eliminate many prop related problems. We designed it to reduce vibration and to help keep the propeller on your motor shaft but still protect the prop.

Many of the problems flyers have start with how they hold their transmitter. Don't use your thumbs to fly your plane. Pinch the sticks of the transmitter on at least the side with the elevons or ailerons-elevator control. This gives you more than one point of reference as to where the stick is smooths out your flight and keeps you from accidentally over-controlling the plane.

Don't move your sticks too far. Most precision flyers move the sticks only about 1/2" from the center position unless they are doing stunts especially on take off and landings. The pilot needs to move the stick slowly and wait for the plane to react.

Don't bump the sticks!!! It makes you look like a beginner and feel out of control. When you bump instead of making a slow smooth motion your plane won't fly smooth and will feel out of control because you move the stick too far and too fast and the plane doesn't have time to react. This flight problem has nothing to do with the plane but is solely due to the way the pilot holds and manages his transmitter.

Take a look at this optical illusion and realize your plane color and rotation can fool your eyes and cause you to become disoriented. If you can't see it you can't fly it. https://i.redd.it/aebt6ho1mfp11.gif

Your color choices can help you stay oriented and fly better. There is a reason that airport wind socks are orange. There are colors that are more visible in the air. If you can't see your plane or are able to stay oriented to it you will crash. Red, white, orange, dark blue, and black are colors that are visible against a cloudy sky but they need to have some contrast with white to stand out against a blue sky. Colors like purple, yellow, pink, or any pastel colors can fade out in the air even though they look great on the ground. I have seen planes that are difficult to fly just because of their color scheme.

It is important to use different patterns on the top and bottom of the plane. I like to put stripes side to side on the bottom of my flying wings and front to back stripes on the top of my planes to help with orientation. Large dark circles on a white background show up well. There should be no question whether you are looking at the top or bottom of your plane from a distance. It is important to get a good color scheme to help with orientation. Keeping the plane close also helps.

A good launch needs to get the plane level, flying straight and with enough speed. Our videos show many launches that look easy because we have done it thousands of times, but there is a touch to getting it right. We see many new flyers who spin the plane like a Frisbee and blame the crash on the plane. If one wing tip is moving faster than the other it will have more air over the wing so it will have more lift so the plane will roll towards the slower wing. The trick is to release the plane at the right moment when both wings are level and moving at the same speed in the right direction at the horizon. Don't launch too steep or the plane will stall right out of your hand.

Prop torque makes a plane roll the opposite direction the prop is turning. Smaller planes and planes with bigger motors and propellers will tend to roll faster to the left than they will to the right because of the rotational forces of the propeller. You will see planes tend to roll to the left down the runway as the motor accelerates because of the prop torque. Prop torque problems can occur on a hand launch when the plane is moving the slowest and the prop torque is at its peak. A harder faster launch will help to get the plane up to speed to help overcome prop torque on launch.

There are several ways to launch a plane. On some of the videos we launch from the center of the plane and then power up when the plane is our of our hand. One of the other things to notice is how fast you can get your hands back on the transmitter after your launch. Flyers often have already lost control before they have their hands on the sticks and are ready to fly. There is nothing wrong with getting an experienced flyer to launch for you so you can keep both of your hands on the transmitter.

Below are a couple of pictures I got from Howard showing his launch technique – He says "I add throttle to trim the weight in my hand to near nothing, then arc up and toward horizontal, until it flies out of my hand. Couldn’t be less stress." There are also a couple of demo videos that show launching techniques.

Don't move your sticks too far. Most precision flyers move the sticks only about 1/2" from the center position unless they are doing stunts especially on take off and landings. The pilot needs to move the stick slowly and wait for the plane to react.

Don't bump the sticks!!! It makes you look like a beginner and feel out of control. When you bump instead of making a slow smooth motion your plane won't fly smooth and will feel out of control because you move the stick too far and too fast and the plane doesn't have time to react. This flight problem has nothing to do with the plane but is solely due to the way the pilot holds and manages his transmitter.

Take a look at this optical illusion and realize your plane color and rotation can fool your eyes and cause you to become disoriented. If you can't see it you can't fly it. https://i.redd.it/aebt6ho1mfp11.gif

Your color choices can help you stay oriented and fly better. There is a reason that airport wind socks are orange. There are colors that are more visible in the air. If you can't see your plane or are able to stay oriented to it you will crash. Red, white, orange, dark blue, and black are colors that are visible against a cloudy sky but they need to have some contrast with white to stand out against a blue sky. Colors like purple, yellow, pink, or any pastel colors can fade out in the air even though they look great on the ground. I have seen planes that are difficult to fly just because of their color scheme.

It is important to use different patterns on the top and bottom of the plane. I like to put stripes side to side on the bottom of my flying wings and front to back stripes on the top of my planes to help with orientation. Large dark circles on a white background show up well. There should be no question whether you are looking at the top or bottom of your plane from a distance. It is important to get a good color scheme to help with orientation. Keeping the plane close also helps.

A good launch needs to get the plane level, flying straight and with enough speed. Our videos show many launches that look easy because we have done it thousands of times, but there is a touch to getting it right. We see many new flyers who spin the plane like a Frisbee and blame the crash on the plane. If one wing tip is moving faster than the other it will have more air over the wing so it will have more lift so the plane will roll towards the slower wing. The trick is to release the plane at the right moment when both wings are level and moving at the same speed in the right direction at the horizon. Don't launch too steep or the plane will stall right out of your hand.

Prop torque makes a plane roll the opposite direction the prop is turning. Smaller planes and planes with bigger motors and propellers will tend to roll faster to the left than they will to the right because of the rotational forces of the propeller. You will see planes tend to roll to the left down the runway as the motor accelerates because of the prop torque. Prop torque problems can occur on a hand launch when the plane is moving the slowest and the prop torque is at its peak. A harder faster launch will help to get the plane up to speed to help overcome prop torque on launch.

There are several ways to launch a plane. On some of the videos we launch from the center of the plane and then power up when the plane is our of our hand. One of the other things to notice is how fast you can get your hands back on the transmitter after your launch. Flyers often have already lost control before they have their hands on the sticks and are ready to fly. There is nothing wrong with getting an experienced flyer to launch for you so you can keep both of your hands on the transmitter.

Below are a couple of pictures I got from Howard showing his launch technique – He says "I add throttle to trim the weight in my hand to near nothing, then arc up and toward horizontal, until it flies out of my hand. Couldn’t be less stress." There are also a couple of demo videos that show launching techniques.

|

|

|

Here is a fun video of Steel launching a flying wing. Steel was 13 years old when this video was shot. He figured out how to throttle up without having his plane fly out of his hand until he was ready. There are a lot of ways to get a plane in the air. This method works for many flyers especially with larger hand launched airplanes as seen in the previous video too.

|

|

|

Motor thrust angle and torque affects the direction and roll of a plane. When you adjust the throttle you may see that the plane pulls up or down. If this is the case, then either the motor thrust angle or the center of gravity needs to be adjusted. Flying wings have reflex, which means the elevons are set slightly upward to help the plane fly straight at half throttle. This little bit of up-trim may pull the nose of the plane up at higher speeds but is normal for all flying wings.

To correct the motor angle, fly the plane to a safe height for a test and trim the plane during a glide to fly flat and level. Give the plane some throttle and see if the plane pulls up or down. If the plane pulls up with increased throttle, you need to tip the motor down. (This is the same for motors in the front or back.)

You will notice the plane may fly level, but will start to roll when the throttle is changed. This is usually due to prop torque and will have to be accounted for by the pilot as he flies. There’s not much to do mechanically to change it. Fliers will ask why their plane is rolling or turning better one way than the other. Because your prop is turning one direction the plane tends to turn easier the other direction.

If your plane rolls over as you loop, the center of gravity may be too far back, or you may have too much movement in the elevator, or a warped wing. If the plane stalls easily or you can’t pull the nose up when gliding, you may not have enough power, your servos may be too small for your plane or you might have the center of gravity too far forward.

To correct the motor angle, fly the plane to a safe height for a test and trim the plane during a glide to fly flat and level. Give the plane some throttle and see if the plane pulls up or down. If the plane pulls up with increased throttle, you need to tip the motor down. (This is the same for motors in the front or back.)

You will notice the plane may fly level, but will start to roll when the throttle is changed. This is usually due to prop torque and will have to be accounted for by the pilot as he flies. There’s not much to do mechanically to change it. Fliers will ask why their plane is rolling or turning better one way than the other. Because your prop is turning one direction the plane tends to turn easier the other direction.

If your plane rolls over as you loop, the center of gravity may be too far back, or you may have too much movement in the elevator, or a warped wing. If the plane stalls easily or you can’t pull the nose up when gliding, you may not have enough power, your servos may be too small for your plane or you might have the center of gravity too far forward.

Don't have too much movement in the flight surfaces. More movement does not make your plane fly better. If your elevons move too far the air flowing over the wing is disrupted and the plane can stall and spin or snap roll when it is not expected. We use big elevons to get smoother air flow. They only have to move a little bit to have a lot of affect on the control of the plane. If you watch the videos of us flying you can see how aerobatic our planes are even though we have a small amount of movement. This control comes from having the center of gravity in the right place, a light plane and the right amount of movement in the control surfaces. Aileron movement affects rolls. Elevator is up and down but when you get too much elevator movement the plane will snap roll or spin.

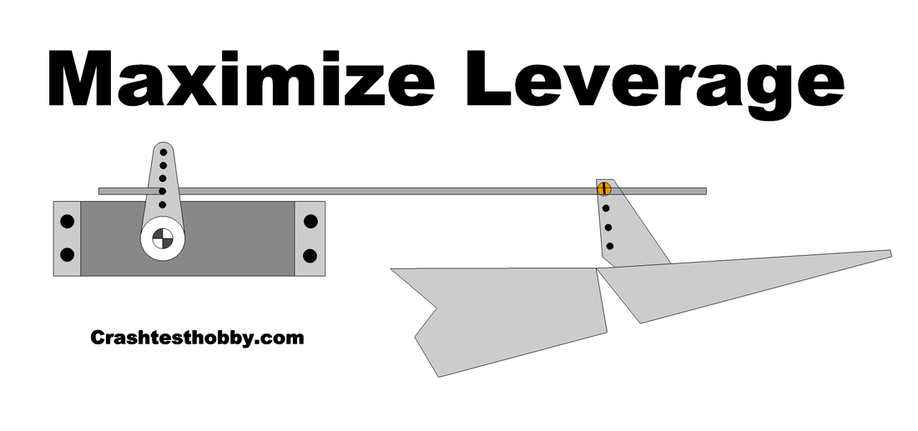

You can double the strength of your servos by the way you connect them to the elevon horns!!!

Push rod should go from the second hole out on the servo arm to the top hole in the horn.

One of the most common RC mistakes is the servo gets overloaded and fails under high stress.

Leverage problems are difficult to see on the workbench but happen in the air with the forces of flight.

Stress your elevons and linkages as a test before flying. Make sure everything is solid and not flexing or moving.

Set your linkages up as shown in the drawing below.

Glue your servo so it is solid in the wing and cannot move under extreme pressure.

Make sure your elevon horns are tight in the elevons. Loose horns can be hard to diagnose but can happen on older planes.

Use a push rod guide to keep the wire from flexing under compression.

If the push rods flex your plane will not be easy to fly.

You need to be able to turn the servo by moving the elevon from the tip with the radio off without the push rod flexing.

Your elevons must be stiff and not be flexing under stress.

Don't use the programming on the transmitter to reduce throw until you have set up linkages as shown.

You can double the strength of your servos by the way you connect them to the elevon horns!!!

Push rod should go from the second hole out on the servo arm to the top hole in the horn.

One of the most common RC mistakes is the servo gets overloaded and fails under high stress.

Leverage problems are difficult to see on the workbench but happen in the air with the forces of flight.

Stress your elevons and linkages as a test before flying. Make sure everything is solid and not flexing or moving.

Set your linkages up as shown in the drawing below.

Glue your servo so it is solid in the wing and cannot move under extreme pressure.

Make sure your elevon horns are tight in the elevons. Loose horns can be hard to diagnose but can happen on older planes.

Use a push rod guide to keep the wire from flexing under compression.

If the push rods flex your plane will not be easy to fly.

You need to be able to turn the servo by moving the elevon from the tip with the radio off without the push rod flexing.

Your elevons must be stiff and not be flexing under stress.

Don't use the programming on the transmitter to reduce throw until you have set up linkages as shown.

|

|

|

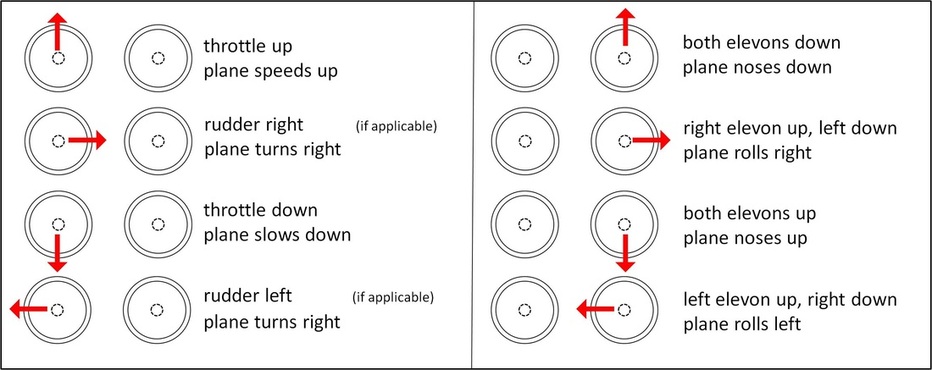

Program your radio correctly -

Don't have too much movement in your flight surfaces or your plane will snap roll and be hard to control.

You want the elevon to move up 3/8" and down 3/8" with aileron roll.

You want the elevon to move up 3/8 and down 3/8" with elevator or up and down movement.

If your linkages are set up as shown above you shouldn't have to reduce throws on the transmitter.

You can double the power of your servo by how you connect your push rods.

You want your servo to turn all the way but only give the desired amount of movement in your elevons

The bottom diagram describes elevon movements with you standing behind the plane.

All flying wings have a little reflex or about 1/4' up trim on the elevons. This is normal.

Don't have too much movement in your flight surfaces or your plane will snap roll and be hard to control.

You want the elevon to move up 3/8" and down 3/8" with aileron roll.

You want the elevon to move up 3/8 and down 3/8" with elevator or up and down movement.

If your linkages are set up as shown above you shouldn't have to reduce throws on the transmitter.

You can double the power of your servo by how you connect your push rods.

You want your servo to turn all the way but only give the desired amount of movement in your elevons

The bottom diagram describes elevon movements with you standing behind the plane.

All flying wings have a little reflex or about 1/4' up trim on the elevons. This is normal.

Anything that pokes up or out of the wing airfoil pattern will disrupt air flow.

We have to live with servo arms. control horns, push rods and an occasional battery plug but even these parts decrease the glide and increase the energy consumed. FPV requires more individual components and all of them need to be buried so they don't disturb air flow and create turbulence. Your plane will fly better if you bury the components. The top of the wing is more sensitive to this disruption than the bottom of the wing or the fuselage.

I know we leave some of our wires exposed and aerodynamically that is a crime. Anything that disrupts the airflow over the wing where the lift is created will kill lift. Wind tunnel tests show something as thin as a piece of scotch tape can disrupt airflow and change the lift. LED lights stuck to the outside of the laminate really kill lift especially if they are on the top of the wing. LED lights should be buried in the foam and covered with laminate for the plane to fly its best.

Take a look at spoilers on gliders. All they do is disrupt the air over the wing and the plane drops out of the sky. A lot of the FPV gear sticks up in the air flow and kills lift. LED lights kill lift if they are left exposed. The worse violator we frequently see is the flat front of the GoPro camera. I like the video quality of the GoPro but it does not have an aerodynamic shape. For this reason I use the Mobius Camera instead. Even on a plane as big as the Herc I can feel the difference in the way the plane flies with a GoPro on it.

Keep the airflow over the wing as smooth and undisturbed as possible!!

Make sure you are using low temp glue stick with a low temp glue gun.

We have seen high temp hot glue sticks used with a low temp glue gun. The hot glue may flow but won't penetrate or stick to the servos, control horns, wing dowels or motor pods and sometimes even the foam. Hot glue is my favorite way to build because I can build clean and fast, but you have to get the right glue at the right temperature.

Another glue problem you need to be aware of in hot weather or if you paint your plane black or another dark color or let your plane sit on a black hot road in the sun or if your plane is left in a hot car, is your hot glue may melt and get soft. I have had a couple of control horns pull out in extremely hot weather. I have also see servos come out in hot weather. I think their black color may have had something to do with it.

I have also learned to be aware of the temperature and protect my planes from extreme heat because heat can also warp a wing or elevon or aileron as the laminate reacts to the high temperature. Wing warping can also happen with uncovered wings like on the Albatross or the Pelican. This is a rare problem but something that happens in hot climates or more often in cars on hot days.

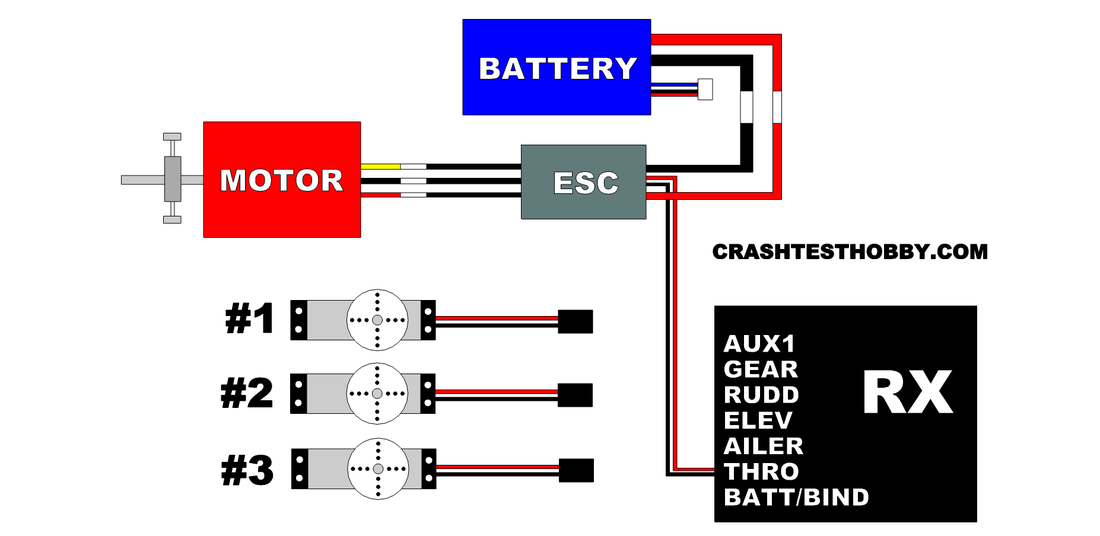

Set up your power train correctly

The throttle position varies between radio brands.

You need to know where your throttle output on your receiver is to know where to plug in your ESC.

Do you have the right set up for your size and speed of plane?

Do you have the right battery and ESC for the motor and prop you are using?

Using the wrong propeller for the speed you want to fly and the size of your plane is a common set up problem

Is your battery, ESC and motor hot after you fly? If so use a smaller prop or bigger motor, ESC and battery.

The sound my motor makes often is a clue that I have a prop, battery, or set up problem.

Read below for more information on each of the components and how to set up and trouble shoot your system.

Even I have had my prop on backwards recently. It is easy to do and sometimes hard to diagnose.

Weak batteries have also frustrated many flyers who thought they had different problems.

Trade out parts one at a time if you are having trouble diagnosing a problem.

Try a different battery, ESC and motor if you lack power or have the motor cutting out.

We have to live with servo arms. control horns, push rods and an occasional battery plug but even these parts decrease the glide and increase the energy consumed. FPV requires more individual components and all of them need to be buried so they don't disturb air flow and create turbulence. Your plane will fly better if you bury the components. The top of the wing is more sensitive to this disruption than the bottom of the wing or the fuselage.

I know we leave some of our wires exposed and aerodynamically that is a crime. Anything that disrupts the airflow over the wing where the lift is created will kill lift. Wind tunnel tests show something as thin as a piece of scotch tape can disrupt airflow and change the lift. LED lights stuck to the outside of the laminate really kill lift especially if they are on the top of the wing. LED lights should be buried in the foam and covered with laminate for the plane to fly its best.

Take a look at spoilers on gliders. All they do is disrupt the air over the wing and the plane drops out of the sky. A lot of the FPV gear sticks up in the air flow and kills lift. LED lights kill lift if they are left exposed. The worse violator we frequently see is the flat front of the GoPro camera. I like the video quality of the GoPro but it does not have an aerodynamic shape. For this reason I use the Mobius Camera instead. Even on a plane as big as the Herc I can feel the difference in the way the plane flies with a GoPro on it.

Keep the airflow over the wing as smooth and undisturbed as possible!!

Make sure you are using low temp glue stick with a low temp glue gun.

We have seen high temp hot glue sticks used with a low temp glue gun. The hot glue may flow but won't penetrate or stick to the servos, control horns, wing dowels or motor pods and sometimes even the foam. Hot glue is my favorite way to build because I can build clean and fast, but you have to get the right glue at the right temperature.

Another glue problem you need to be aware of in hot weather or if you paint your plane black or another dark color or let your plane sit on a black hot road in the sun or if your plane is left in a hot car, is your hot glue may melt and get soft. I have had a couple of control horns pull out in extremely hot weather. I have also see servos come out in hot weather. I think their black color may have had something to do with it.

I have also learned to be aware of the temperature and protect my planes from extreme heat because heat can also warp a wing or elevon or aileron as the laminate reacts to the high temperature. Wing warping can also happen with uncovered wings like on the Albatross or the Pelican. This is a rare problem but something that happens in hot climates or more often in cars on hot days.

Set up your power train correctly

The throttle position varies between radio brands.

You need to know where your throttle output on your receiver is to know where to plug in your ESC.

Do you have the right set up for your size and speed of plane?

Do you have the right battery and ESC for the motor and prop you are using?

Using the wrong propeller for the speed you want to fly and the size of your plane is a common set up problem

Is your battery, ESC and motor hot after you fly? If so use a smaller prop or bigger motor, ESC and battery.

The sound my motor makes often is a clue that I have a prop, battery, or set up problem.

Read below for more information on each of the components and how to set up and trouble shoot your system.

Even I have had my prop on backwards recently. It is easy to do and sometimes hard to diagnose.

Weak batteries have also frustrated many flyers who thought they had different problems.

Trade out parts one at a time if you are having trouble diagnosing a problem.

Try a different battery, ESC and motor if you lack power or have the motor cutting out.

We include clear laminate in our kits. We get a lot of questions about how to laminate correctly. See the videos below and watch the techniques.

There is a secret. When you laminate keep the iron cool. The laminate sticks from about 180 degrees to 220 degrees. You want to stay as close to the bottom temperature as possible. The higher temperature will melt and distort the foam and warp the wing. Water boils at 210 degrees so if you put a drop of water on the iron you can get an idea if the iron is at the right temperature. It is easier to get the temperature right if you get an inferred thermometer to laminate. Before you start ironing on the wing and elevons take a few laminate scraps and iron them to your box. Turn your iron down to where the laminate just barely sticks without wrinkles. After the laminate is stuck down you can turn the iron up a little for a final once over to make sure it is stuck down and shrunk as needed.

I now use a regular clothing iron rather than a hobby iron because hobby irons do not have good thermostat control. I also like the fact the clothing iron will heat in about 15 seconds and they don't fluctuate much in temperature. Hobby irons temperature can fluctuate wildly. In testing they can have a 50 F degree swing without changing the setting. I have also seen a 30 degree variation from the tip of the iron to the heel of the iron which makes setting the temperature difficult. My hobby irons tend to overheat if I leave them on the bench for too long between times they are used. I keep a wet rag on the bench and cool the iron if it has been sitting so I don't cause problems with the laminate... especially on the elevons. I have used a water spray bottle before to cool the iron but it may get moisture in the wing and edges and keep them from sticking.

If you are using a clothing iron do not let your wife iron her clothing with it after you have laminated with it because laminating leaves a little glue on the iron that will run some clothing. I buy the budget irons at the local department store. You don't want to have water in the iron.

Lay out your laminate with about 2" extra on all edges. I like to make a long straight stroke down the middle of the wing as my first stroke of the iron then work the laminate to the edges to get out the wrinkles. If you work from a corner or an edge, the wing can warp. It also helps to get a flat wing if you iron the laminate on the bottom of the wing first.

When the iron is too hot a couple of things happen. First the laminate starts to shrink before it is touching the foam so you get wrinkles. This is more common on the thinner elevons that can quickly overheat. The reason the laminate adhesive doesn't stick as well with too hot of an iron is that the hot glue doesn't cool and set fast enough before the laminate has come back off the overheated foam. Also the hot air expands and leaves air bubbles under the laminate that can lift it off the foam. If your iron is too hot and you try over and over to stick the laminate down, your laminate picks up some overmelt from the foam and then the laminate adhesive is deactivated. Closely watch for distortion in your airfoil and the elevons as you lamiante. The foam melts and changes shape with too hot of an iron so you get flat areas on the wing and thin sections and wrinkles on the elevons?

The laminate we use in our kit is the easiest laminate to control I have used. It is stronger and easier to apply because it doesn't shrink as much as Monocoat or Ultracoat and doesn't split with a hard landing. You will do a better job if you understand its properties before you use it the first time. You need to learn a how it behaves at different temperatures. The second plane is always easier than the first. Several of our plane videos show how to laminate so watch the demonstrations before you start.

The advantages of our clear laminate are:

We include it in the kit at no extra charge.

It offers great UV protection of the foam and of the Extreme Tape.

It doesn’t need a spray adhesive (3M90 or 3M77) to get it to stick.

If you use a spray adhesive you are adding weight to your plane.

It is stronger than Ultracoat.

It is easier to apply because it has less shrinkage.

Repairs and wrinkles are almost invisible because the laminate is clear.

You can see the structure of the plane through the covering making it easier to see if there is damage.

You can add decals and colored packing tape to get color.

You can use holographic tape that adds a 3D dimension to the appearance of the plane.

The clear laminate is the product of choice If you are adding LED lights.

We still see a lot of planes covered with the Ultracoat. They do look good. I have used it myself.

|

|

|

This preflight checklist will help you inspect your plane.

1. MOTOR AND PROPELLER

Is the propeller on with the writing facing forward?

Is the motor running forward?

Does my motor look, sound, and feel like it is running well?

Do I have enough power?

Motor angle is an important part of a design but:

Is the motor mount bent angling the motor up or down when it shouldn’t be?

Is the motor angled to one side when it shouldn’t be?

Is the propeller chipped or cracked, or out of balance?

Is the motor mount cracked or loose?

Are the screws tight that hold the motor on?

Is all wiring secured?

Is my prop adapter tight?

Is my O-ring in good condition?

Are my ESC and battery appropriate for this size of motor?

2. ESC

Is my ESC the right size and type for the motor?

Have I trimmed the throttle on the transmitter so my ESC isn't prematurely starting

Can it handle the amperage the motor will draw?

Does my ESC turn off the motor if the battery voltage drops below 3.2 volts per cell?

Is my ESC programmed for a fast start and brake/no brake as desired?

Is it ventilated so it won’t overheat?

Are the plugs to the receiver and motor wires well soldered tight and secure?

3. BATTERY

Is the battery the appropriate size for the motor?

Is the battery charged?

Is the battery balanced? (all cells of the battery within 0.5 volts of each other?)

Is the battery damaged in any way?

Is my battery puffed or swollen?

Is my battery old and weak and not holding a charge?

Is the battery secured in the plane well enough to keep it from ejecting it in an accident?

4. RECEIVER AND TRANSMITTER

Is my transmitter charged?

Is my receiver bound to the transmitter?

Is my transmitter or receiver damaged in any way?

Have this transmitter and receiver been dependable in the past?

Is my receiver radio range appropriate for my size of plane?

Is the receiver antenna intact and routed where it has maximum range?

Is the receiver well secured where it is away from vibration and electrical interference?

Are the servo and ESC plugs tight and secure and in good repair?

Did I do a range check? …. (check your owner's manual)

5. SERVOS AND LINKAGES

Are my servos set up for maximum leverage? See drawing above.

Are the servos big enough for my plane?

Do I have the right amount of movement on the flight surfaces?

(In most cases 3/8″ up and 3/8″ down is recommended movement on a flying wing.)

We use big elevons. Too much movement can cause snap rolls.

Have I set the reflex (slight up trim) properly?

(On a flying wing, there’s usually 1/4″ up-trim when the servos are centered)

Can I stall the servo by applying pressure to the elevon, aileron, or elevator?

If you can stall your servos by pressing on the control surface, the chances are that your servos are too small or too weak.

Are the linkages loose or is there any slop?

Are my hinge lines tight without tears or slop?

(Can I move the pushrods, elevator, rudder, elevons or ailerons without moving the servo arm?)

Is the hinge line tight and secure?

Are the servo wires in good repair and well secured?

Are the set screws in the servo horns present and tight?

Are the horns on the flight surface tight and secure?

Are the screws in the servo that hold on the arms present and tight in the servo?

Are the snap rings on the EZ connectors tight and in place?

6. PLANE INSPECTION

Is the plane appropriate for my skill level?

Does my plane balance properly on the CG?

Is my my name and phone number in a visible place on my plane?

Is the plane too heavy for its size?

Has the plane been sitting in a hot car where my hot glue may have gotten soft?

Is the plane built well?

Is there any structural damage to the plane that needs to be repaired?

Is the plane balanced on the appropriate CG for this model?

Is the motor mount secure?

Are all wires secure and not going to rub on the motor as it turns?

Is the wing secured and strong enough for loops and rolls?

Are all tail surfaces well attached and aligned?

Did I use the right glue the right way when the plane was built?

Are all of the horns on the surfaces intact and well secured?

Is landing gear secured and in good repair?

7. RADIO PROGRAMMING

Is my radio programmed correctly? See diagram above.

Are my flight surfaces moving the right direction?

Is the movement on the flight surfaces appropriate for this type of plane?

Even experienced flyers frequently make mistakes on programming.

(Stand behind the plane to look and make sure the surfaces are moving in the right direction.)

8. FLYING FIELD

Do I need permission to fly on this flying field?

Will the property owners be offended that I am flying over their property?

Is my plane quiet enough for this flying are so people are not disturbed?

Do I have enough open space to fly safely?

Where is the nearest airport? Is there a chance of live air traffic?

What are the altitude restrictions for RC in this area?

Are there people in my flying area? Will they be offended that I am flying?

Will I have to fly over heads of spectators, creating a safety concern?

Do I have a flight line for spectators that should determine my flight plan?

How is the weather?

What is the predominate wind direction?

Where should I stand on the field so I can take off and land into the wind?

9. PROPER TRAINING

Do I need some help to fly this type of plane?

Do I have a qualified trainer who knows what he is doing?

Did he inspect the plane with me?

Do I understand what he is telling me?

Have I spent time on a buddy cord or simulator with a similar plane?

Do I fly by pinching the stick not just flying with thumbs on the sticks

Do I know how to launch my plane properly?

Can I handle a radio in one hand while I launch with the other?

Is my hand out of the way of the propeller?

Do I have a first aid kit?

10. PILOT READY TO FLY

Am I sober?

Do I need glasses? (I have seen nearly blind people trying to learn to fly)

Am I being considerate of others?

Have I finished the checklist and know I am ready to fly?

Are there any equipment or safety concerns I have not addressed?

Do I have other planes or equipment under my feet I could stumble on?

Have I alerted everyone that I am taking off.

Am I ready to have a great time?

Go through this checklist before you fly, and go through it again after any accident or plane modification.

Happy flying!

-Lee

Is the propeller on with the writing facing forward?

Is the motor running forward?

Does my motor look, sound, and feel like it is running well?

Do I have enough power?

Motor angle is an important part of a design but:

Is the motor mount bent angling the motor up or down when it shouldn’t be?

Is the motor angled to one side when it shouldn’t be?

Is the propeller chipped or cracked, or out of balance?

Is the motor mount cracked or loose?

Are the screws tight that hold the motor on?

Is all wiring secured?

Is my prop adapter tight?

Is my O-ring in good condition?

Are my ESC and battery appropriate for this size of motor?

2. ESC

Is my ESC the right size and type for the motor?

Have I trimmed the throttle on the transmitter so my ESC isn't prematurely starting

Can it handle the amperage the motor will draw?

Does my ESC turn off the motor if the battery voltage drops below 3.2 volts per cell?

Is my ESC programmed for a fast start and brake/no brake as desired?

Is it ventilated so it won’t overheat?

Are the plugs to the receiver and motor wires well soldered tight and secure?

3. BATTERY

Is the battery the appropriate size for the motor?

Is the battery charged?

Is the battery balanced? (all cells of the battery within 0.5 volts of each other?)

Is the battery damaged in any way?

Is my battery puffed or swollen?

Is my battery old and weak and not holding a charge?

Is the battery secured in the plane well enough to keep it from ejecting it in an accident?

4. RECEIVER AND TRANSMITTER

Is my transmitter charged?

Is my receiver bound to the transmitter?

Is my transmitter or receiver damaged in any way?

Have this transmitter and receiver been dependable in the past?

Is my receiver radio range appropriate for my size of plane?

Is the receiver antenna intact and routed where it has maximum range?

Is the receiver well secured where it is away from vibration and electrical interference?

Are the servo and ESC plugs tight and secure and in good repair?

Did I do a range check? …. (check your owner's manual)

5. SERVOS AND LINKAGES

Are my servos set up for maximum leverage? See drawing above.

Are the servos big enough for my plane?

Do I have the right amount of movement on the flight surfaces?

(In most cases 3/8″ up and 3/8″ down is recommended movement on a flying wing.)

We use big elevons. Too much movement can cause snap rolls.

Have I set the reflex (slight up trim) properly?

(On a flying wing, there’s usually 1/4″ up-trim when the servos are centered)

Can I stall the servo by applying pressure to the elevon, aileron, or elevator?

If you can stall your servos by pressing on the control surface, the chances are that your servos are too small or too weak.

Are the linkages loose or is there any slop?

Are my hinge lines tight without tears or slop?

(Can I move the pushrods, elevator, rudder, elevons or ailerons without moving the servo arm?)

Is the hinge line tight and secure?

Are the servo wires in good repair and well secured?

Are the set screws in the servo horns present and tight?

Are the horns on the flight surface tight and secure?

Are the screws in the servo that hold on the arms present and tight in the servo?

Are the snap rings on the EZ connectors tight and in place?

6. PLANE INSPECTION

Is the plane appropriate for my skill level?

Does my plane balance properly on the CG?

Is my my name and phone number in a visible place on my plane?

Is the plane too heavy for its size?

Has the plane been sitting in a hot car where my hot glue may have gotten soft?

Is the plane built well?

Is there any structural damage to the plane that needs to be repaired?

Is the plane balanced on the appropriate CG for this model?

Is the motor mount secure?

Are all wires secure and not going to rub on the motor as it turns?

Is the wing secured and strong enough for loops and rolls?

Are all tail surfaces well attached and aligned?

Did I use the right glue the right way when the plane was built?

Are all of the horns on the surfaces intact and well secured?

Is landing gear secured and in good repair?

7. RADIO PROGRAMMING

Is my radio programmed correctly? See diagram above.

Are my flight surfaces moving the right direction?

Is the movement on the flight surfaces appropriate for this type of plane?

Even experienced flyers frequently make mistakes on programming.

(Stand behind the plane to look and make sure the surfaces are moving in the right direction.)

8. FLYING FIELD

Do I need permission to fly on this flying field?

Will the property owners be offended that I am flying over their property?

Is my plane quiet enough for this flying are so people are not disturbed?

Do I have enough open space to fly safely?

Where is the nearest airport? Is there a chance of live air traffic?

What are the altitude restrictions for RC in this area?

Are there people in my flying area? Will they be offended that I am flying?

Will I have to fly over heads of spectators, creating a safety concern?

Do I have a flight line for spectators that should determine my flight plan?

How is the weather?

What is the predominate wind direction?

Where should I stand on the field so I can take off and land into the wind?

9. PROPER TRAINING

Do I need some help to fly this type of plane?

Do I have a qualified trainer who knows what he is doing?

Did he inspect the plane with me?

Do I understand what he is telling me?

Have I spent time on a buddy cord or simulator with a similar plane?

Do I fly by pinching the stick not just flying with thumbs on the sticks

Do I know how to launch my plane properly?

Can I handle a radio in one hand while I launch with the other?

Is my hand out of the way of the propeller?

Do I have a first aid kit?

10. PILOT READY TO FLY

Am I sober?

Do I need glasses? (I have seen nearly blind people trying to learn to fly)

Am I being considerate of others?

Have I finished the checklist and know I am ready to fly?

Are there any equipment or safety concerns I have not addressed?

Do I have other planes or equipment under my feet I could stumble on?

Have I alerted everyone that I am taking off.

Am I ready to have a great time?

Go through this checklist before you fly, and go through it again after any accident or plane modification.

Happy flying!

-Lee